Veromatic coffee machines are made with great care, every part has been thought through. There is a lot to consider when designing a coffee machine. The materials, ease of use, functionality, appearance, production, everything must be in perfect order. In this blog, our product designer Hadeer Dinha, tells everything about product design. After reading this blog, you will know everything about his work at Veromatic and what the design process of a coffee machine entails.

Hadeer, what are your activities at Veromatic?

I am mainly involved in designing the coffee machines. My role in the organization is to be at the very beginning of the design process, where I map out the needs of different stakeholders (the end user, the customer, our different departments) and translate that into a product design. With this, I try to design attractive products that match the market as much as possible, are technically feasible and can be made for series production.

What are the steps of the coffee machine design process?

There are different phases in the design process. We follow these phases and at the end of each phase, we assess whether we can proceed to the next phase. We will go through the following phases:

Exploration phase

- Based on the briefing, we map out the major challenges.

- When knowledge is missing to solve one of the challenges, this knowledge is gathered externally.

Ideas phase

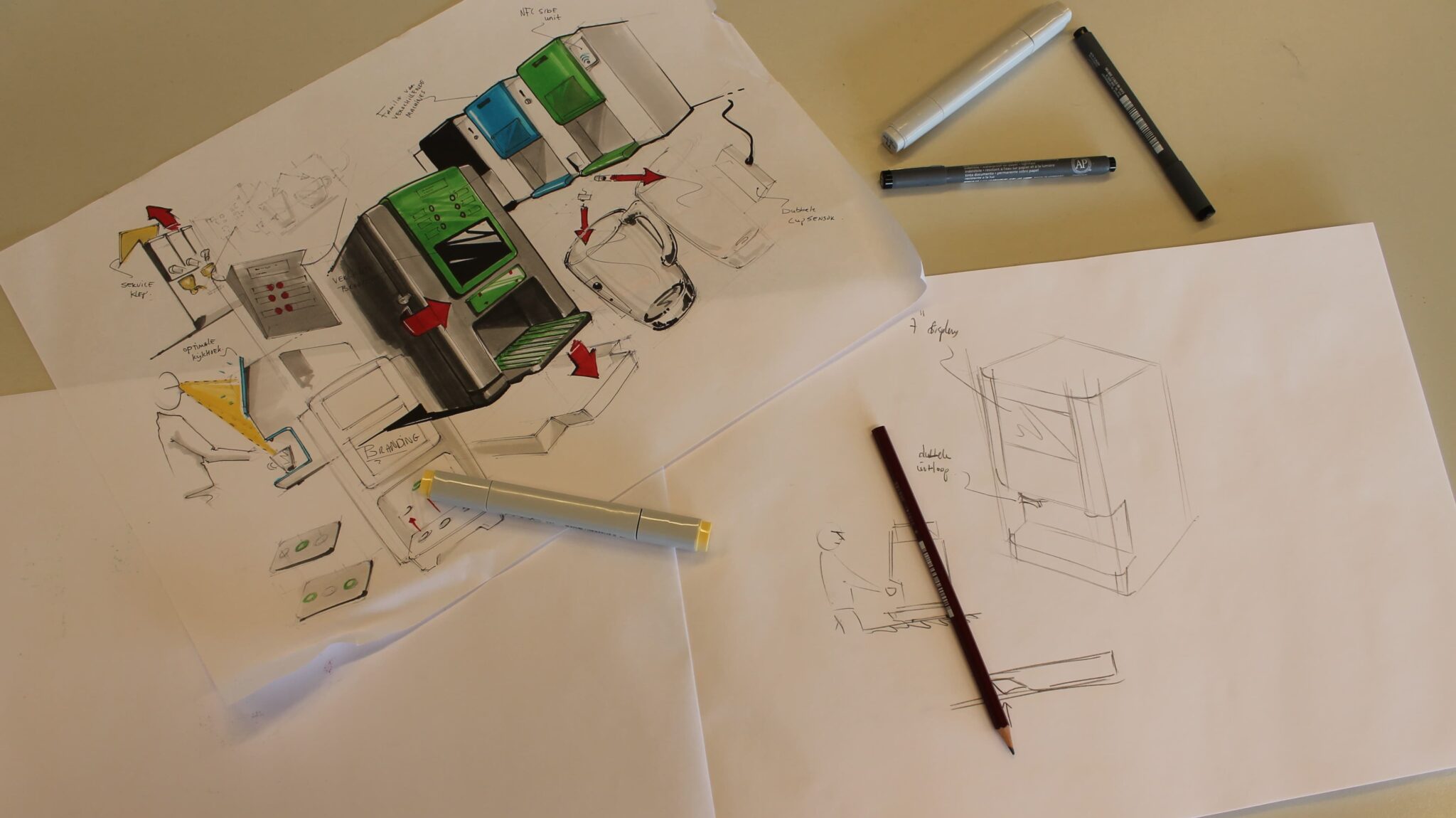

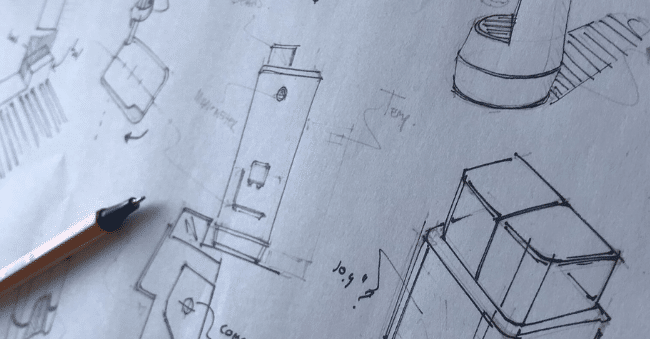

- We then organize multiple brainstorming sessions to generate ideas.

Concept phase

- Then we select a number of interesting ideas and develop them into concepts, determining the form, function and material.

- Then we make a render (3D model) or a physical prototype to better assess the concept.

- We present the concepts to various departments (or directly to the client), so one concept is chosen to continue with.

Elaboration phase

- We develop the concept into a functional prototype, in which the plastic parts are often 3D printed.

- The prototype is tested and assessed.

- We work out improvements into a final design.

Realization phase

- After a design is ready, the suppliers produce the parts. For certain parts, molds must be designed and made before the parts can be produced.

Acceptance phase

- With the first parts produced, we build prototypes that are tested by the clients or end users.

- Then we implement feedback in the design, which means that some molds have to be adjusted.

- Once the molds are approved, we can produce parts for commercial machines.

0-series

- Before we sell machines to customers, we first run a 0-series to test whether all departments and processes are aligned.

- If everything is in order, we will produce the machine for the customers.

Do you want to know more about our coffee machines? Click here!

Do you have an example of a product you designed?

I am both designing new products and redesigning a coffee machine. For example, I have just redesigned the front of a machine with my colleague. First we got certain specifications for the new design. With these specifications in mind, we started brainstorming sessions. We formulated all the challenges and looked at how we were going to solve these technically.

One of the challenges was the cup tray, which had to be adjustable in height. It was not allowed to feel any positions, it had to run smoothly. During a brainstorming session, we looked specifically at this part and then put various ideas on paper. First we solve the problem purely functionally, after which we further optimize the component. Second, we look at how we can further improve the appearance, user-friendliness and costs so that the part becomes attractive in all areas.

What do you pay attention to when you design a coffee machine?

End users and other stakeholders

In general, I always put the end user first, who must of course be satisfied with the product in terms of appearance, quality and especially ease of use. In addition, with every design choice I try to assess the part from different perspectives. This includes the seller, the operator, the mechanic, the manufacturer and the production employee.

Components

From the first sketch I also think about how I can keep the number of parts to a minimum to keep costs limited. This often requires more design time, but it can save a lot of costs afterwards, especially if you have to invest in molds. In addition, you should already have an idea of the production method that will be used for the part, so you can determine the mounting points smartly.

Material

I also pay attention to the material. I am always involved when we visit new suppliers. This way I can assess whether they can deliver the right quality. In addition, we are always looking for sustainable solutions with regard to the material. For example, if we have to use plastic, we check whether the suppliers can supply recycled plastics.

Finally, with every choice you should always try to find the right balance between the quality, the price and the lead time of the product.

What do you do after the concept design?

After the concept design, I transfer the concept to R&D to develop it into a final product. In these phases I monitor the design from the sidelines, so it does not lose its essence. In addition, I also support R&D on a technical level where necessary. I also try to keep an eye on the market in order to identify certain developments and trends in time and to respond to them with new products. Once the prototypes are ready, I provide the right tools to get feedback from customers and end users during the field test. This allows us to further optimize the product. This way we deliver a product that is actually in demand.

What do you like most about designing coffee machines?

Because I speak with suppliers, customers and people from various departments within the organization, I gain a lot of knowledge and see different insights. As a result, I understand the different needs and a total picture is created for me. Collecting all this knowledge and translating it into a suitable and attractive design is what I enjoy most about my job.

How do you keep developing new ideas?

I am always curious and I am observing products around me. This leads to new ideas. I also always try to improve my creativity by looking at a product and imagining how I could improve the design. In addition, I continue to look for inspiration by following trends in the technological and design world. This way you stay up-to-date on the latest options.

Do you want to know more about our coffee machines and the specifications after reading this blog? View all our coffee machines via the button below!